XT60 VS XT60H: A Comprehensive Analysis of Core Parameters and Application Differences

In the field of high-current DC connectors, the XT series has become the mainstream choice for scenarios such as remote control equipment, energy storage power supplies, and power tools due to its excellent reliability and adaptability. Among them, XT60 is widely used as a classic model, while XT60H is its upgraded and optimized version. The two share similarities in core performance parameters but differ significantly in structural design and ease of use. This article will compare the two from four core dimensions: Current, Size, Specs, and Application, and conduct an in-depth analysis of their key differences to provide accurate references for selection.

Core Parameter Comparison Table for XT60 vs XT60H

| VS | XT60 | XT60H |

| Current | Continuous Current: 30A, Instantaneous c: 60A | Continuous Current: 30A (some marked 60A+), Instantaneous Current: 60A (Peak up to 100A) |

| Size (Unit: mm) | No uniformly public overall dimensions; core metal terminal dimensions not clearly marked | Male Connector (XT60H-M): 23.80×20.50×9.20; Female Connector (XT60H-F): 24.00×20.20×8.10; Core Metal Terminal Size: 4.5mm |

| Specs | Rated Voltage: 500V DC; Contact Resistance: 0.55mΩ; Contact Material: Gold-plated Brass; Housing Material: Polyamide; Flame Retardant Rating: UL94 V-0; Operating Temperature: -20~+120℃; Recommended Wire Gauge: 12 AWG; Service Life: 1000 Cycles; No Protective Housing, Heat Shrink Tube Required for Protection | Rated Voltage: 500V DC; Contact Resistance: 0.50~0.8mΩ; Contact Material: Gold-plated Brass; Housing Material: High-temperature Nylon; Flame Retardant Rating: UL94 V-0; Operating Temperature: -20~+120℃; Recommended Wire Gauge: 12~14 AWG; Service Life: 1000 Cycles; With Integrated Protective Housing and Snap-on Insulation Cover |

| Application | Power connection for medium-power equipment such as standard UAVs, remote control vehicles, power tools, toys, and small-to-medium energy storage power supplies | RC quadcopters, UAVs, remote control aircraft/cars/boats, electric bicycles, energy storage power supplies, EV battery packs, solar battery terminals, etc., especially suitable for scenarios requiring high connection reliability and convenience |

In-depth Analysis of Key Differences for XT60 vs XT60H

As can be seen from the comparison of core parameters, XT60 and XT60H are highly consistent in basic electrical performance, and the core differences focus on structural design, ease of use, protection performance, and compatibility. Specifically, they can be summarized into the following 4 points:

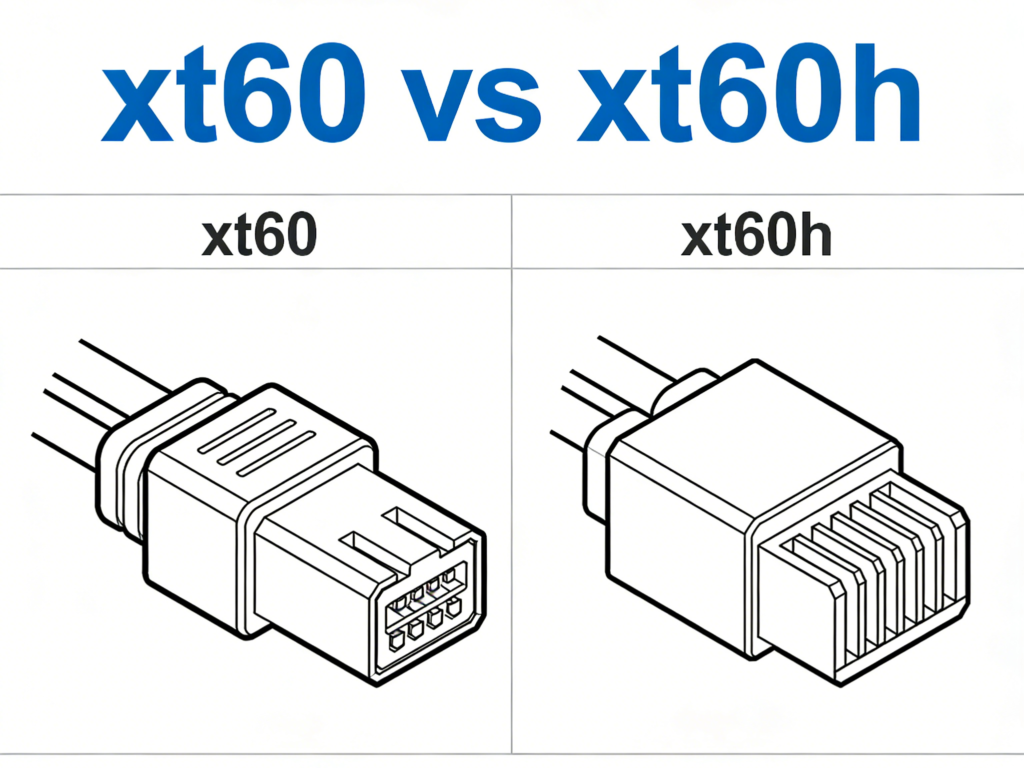

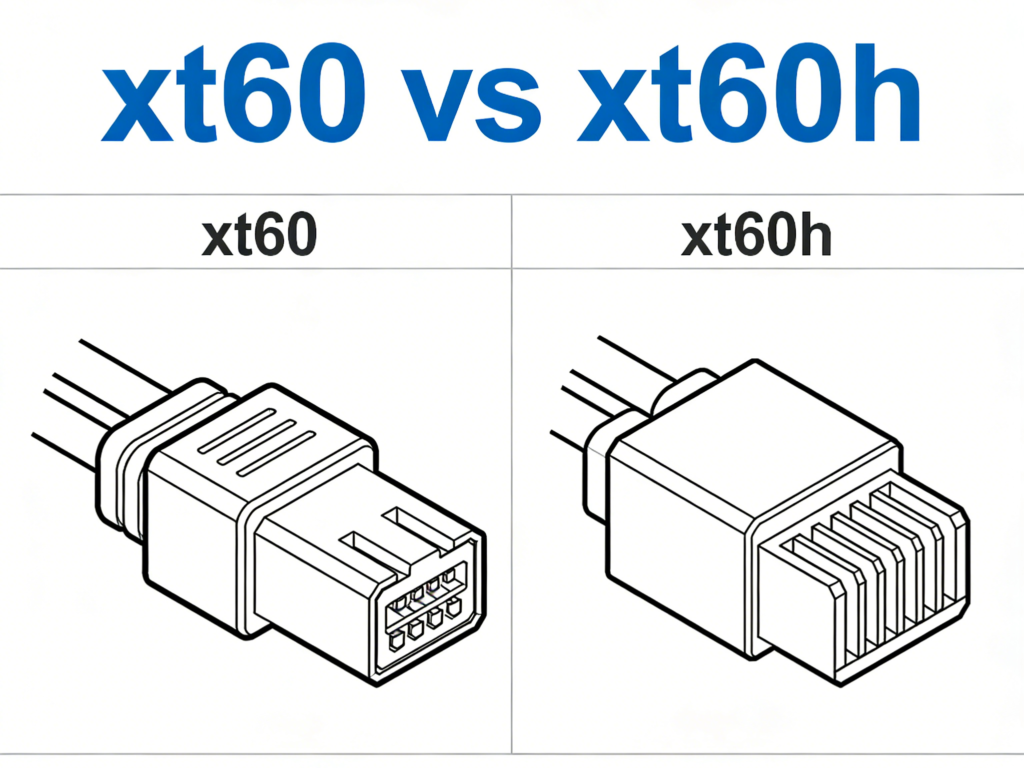

1. XT60 vs XT60H: Structural Design Upgrade

This is the core improvement of XT60H compared to XT60. XT60 adopts an open design without a dedicated protective housing structure. After welding, it is necessary to add a heat shrink tube for insulation and protection of the solder joints; otherwise, problems such as exposed solder joints and bending damage are likely to occur. XT60H, on the other hand, adds an integrated protective housing and a snap-on insulation cover in its design, which can not only directly wrap the solder joints to avoid short circuits and reverse polarity risks but also prevent wire bending from damaging the solder joints, greatly improving the reliability of the connection. At the same time, XT60H optimizes the housing shape and adds an integrated grip area, making plugging and unplugging more convenient and labor-saving, solving the problem of poor hand feel when plugging and unplugging XT60.

2. XT60 vs XT60H: Dimension Details

As a classic model, XT60’s official public information focuses more on electrical parameters, and the labeling of overall external dimensions is relatively vague, bringing certain uncertainty to equipment housing opening and installation layout. XT60H, however, clearly provides precise dimension parameters for male and female battery connectors, and the core metal terminal size is uniformly 4.5mm, allowing designers to achieve precise matching during the equipment structural design stage, reducing installation and adaptation errors, and improving product assembly efficiency. In addition, some data shows that XT60H is shorter and lighter than XT60, making it more adaptable to equipment with strict space and weight restrictions (such as micro UAVs).

3. XT60 vs XT60H: Ease of Use

The installation process of XT60 is relatively cumbersome. After welding, an additional heat shrink tube wrapping process is mandatory, which not only increases the material cost of the heat shrink tube but also extends the construction time. Especially in mass production scenarios, it will significantly increase labor costs. The snap-on insulation cover of XT60H can be directly snapped on, realizing heat shrink tube-free installation, which greatly simplifies the construction process, reduces material and labor costs, and makes on-site maintenance and connector replacement more convenient and efficient.

4. XT60 vs XT60H: Compatibility

As an upgraded version of XT60, XT60H maintains full reverse compatibility in design, that is, the male XT60H can be directly mated with the female XT60, and the female XT60H can also be perfectly adapted to the male XT60. This feature allows equipment that already uses XT60 connectors to be directly upgraded to XT60H without modifying other structures, enjoying the advantages of its protection performance and convenience, without the need for overall system transformation, and reducing upgrade costs.

Selection Recommendations for XT60 vs XT60H

1. If cost-effectiveness is pursued, the equipment installation space is sufficient, and additional heat shrink tube construction is acceptable, XT60 is fully capable of meeting the basic power connection needs of medium-power equipment, suitable for entry-level RC equipment, ordinary electric toys and other scenarios with limited budgets.

2. If high requirements are placed on connection reliability and plug-and-play convenience, or the equipment is used in complex environments (such as outdoor, vibration scenarios) and requires frequent maintenance and replacement, XT60H is recommended as the priority. Its integrated protective housing can effectively protect solder joints, and the heat shrink tube-free design improves construction efficiency. It is especially suitable for professional UAVs, high-performance remote control vehicles, energy storage power supplies, EV battery packs and other scenarios that have strict requirements on connection stability.

Conclusion for XT60 vs XT60H

Essentially, XT60 and XT60H are a “basic model” and an “upgraded model”. There is little difference in core electrical performance. The key difference is that XT60H solves the pain points of XT60 such as exposed solder joints and inconvenient plugging and unplugging by adding a protective housing and optimizing the grip design, and achieves full reverse compatibility. When selecting models, it is necessary to reasonably choose the appropriate model according to the equipment usage scenario, convenience requirements and budget to ensure the safety and stability of the power connection.